NEWS

Jubilee bands are back! Please see the Bands menu selection.

Menus

Note that there are two menus to select information from. Menu 1 is the main menu (shown in red above) and is always in view on each web page. Menu 2, is accessible via a drop down Menu link in the upper right corner of each web page.

Watches

I ordered some custom dials with paint that can be engraved with a laser. The metal is brass so when I burn off the top layer of paint, a nice crisp gold color is revealed. It was difficult to get a crisp photo of the dial but everything on these new custom dials are crisp and sharp. The hour markers have the best luminescent coating and light up really well at night. The watch hands have the same coating material.

08/19/21 AOPA has published a story about me and my custom watch building business. They contacted me and asked if they could interview me about my watch business. I said sure and an interview was scheduled. Below is a link to their published story based on that interview:

Welcome

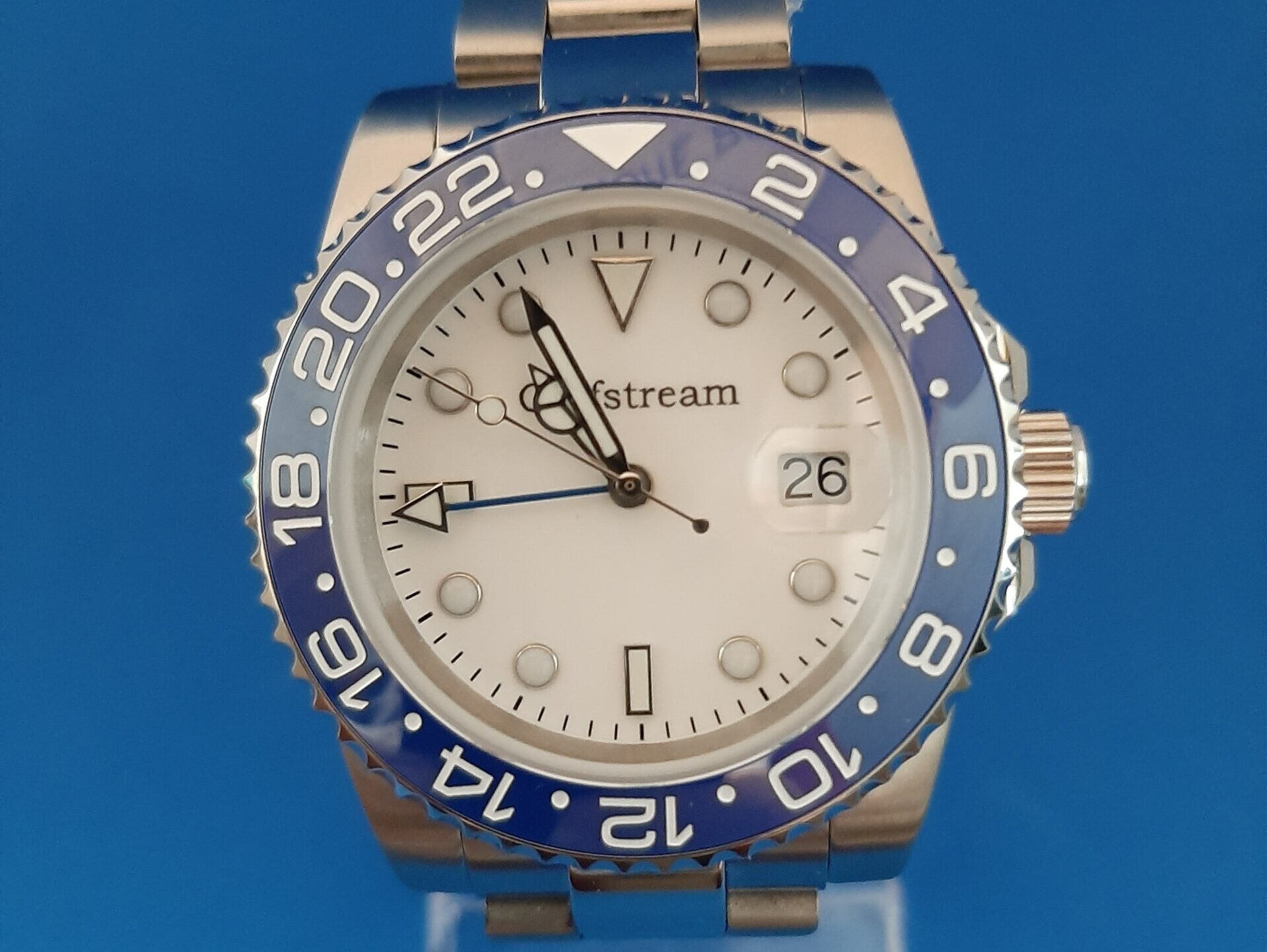

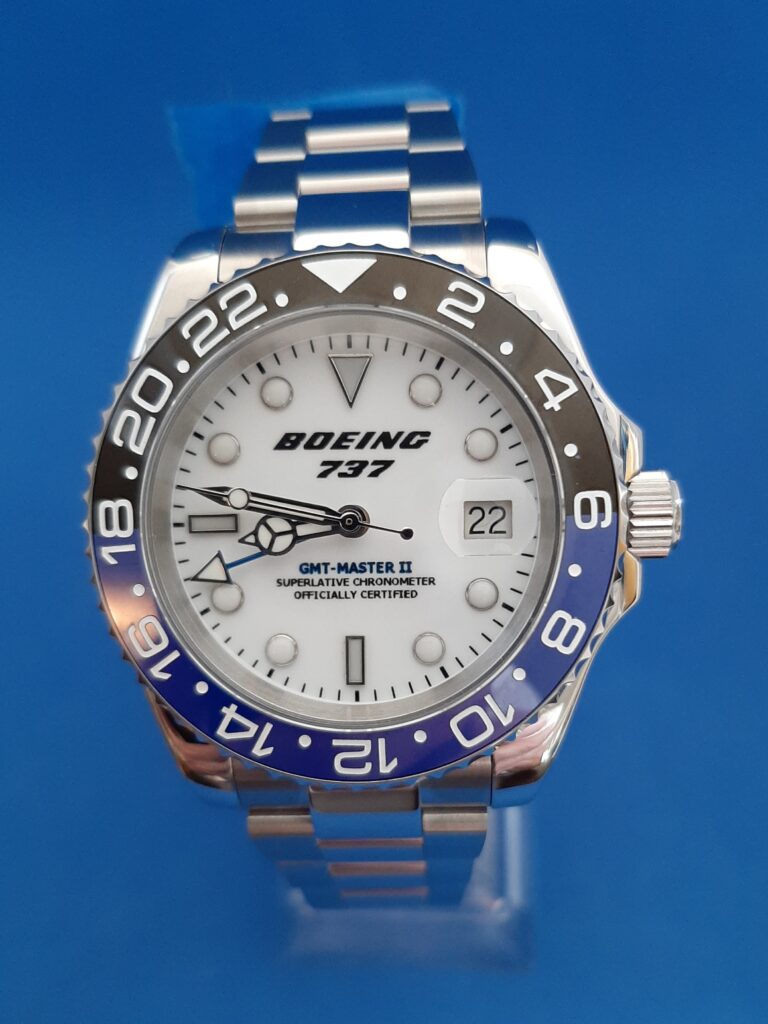

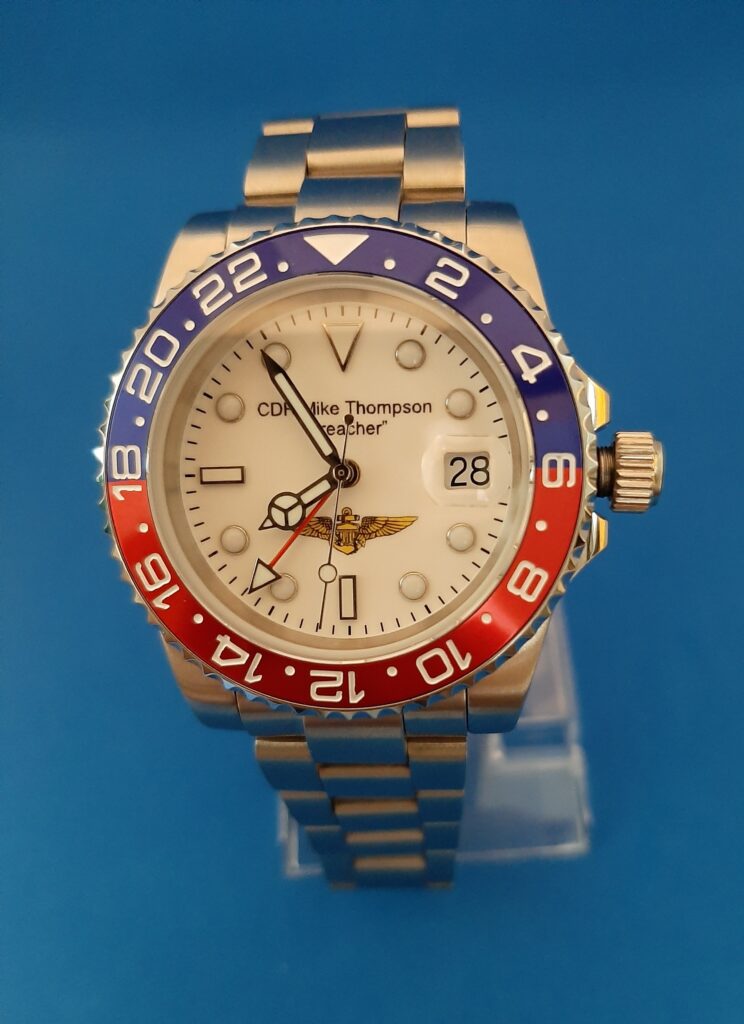

Welcome to the GMT Pilots website. I run a small watch shop and make custom dial GMT watches for pilots. I hand assemble all the watch parts and I source the parts from all over the world.

I can put (almost) any airplane name and/or company name on a watch dial, for yourself or as a gift.

More Watch Photos

White Dials

Above is an example of one of my watches (dial text is not yet customized for a customer). They have a white dial as shown in the above photo.

Black Dials

As it turns out, being able to print using White ink is a very different and expensive process (unfortunately). This capability requires separate and dedicated equipment to print White text on a Black dial. In addition, the amount of time it takes to print on a Black dial is about twice as long as printing on a White dial. The application process is more time consuming. Because of all of this, Black dial GMT pilot watches have a higher price than my White dial watches.

Bi-Directional Bezels

Update: 10/28/21 My main case factory stopped making their GMT cases. I won’t go into the details as to why they stopped except to say it has to do with a very long internal legal battle between ETA (a huge watch movement maker) and Switzerland’s Consumer Protection Agency (they have a different name for it). Really.

The good news is that I’ve found a new case factory that offers bi-directional GMT bezel cases and I am now ordering from them.

What sets my GMT watches apart from all the others being sold is:

- Airplane and/or company name on the dial.

- I use a quartz movement (made in Switzerland).

- The 24 hour hand is fully functional.

- You never have to reset the time if you don’t wear your watch for a few days (the battery keeps the quartz movement powered all the time).

The battery will last approximately three years.

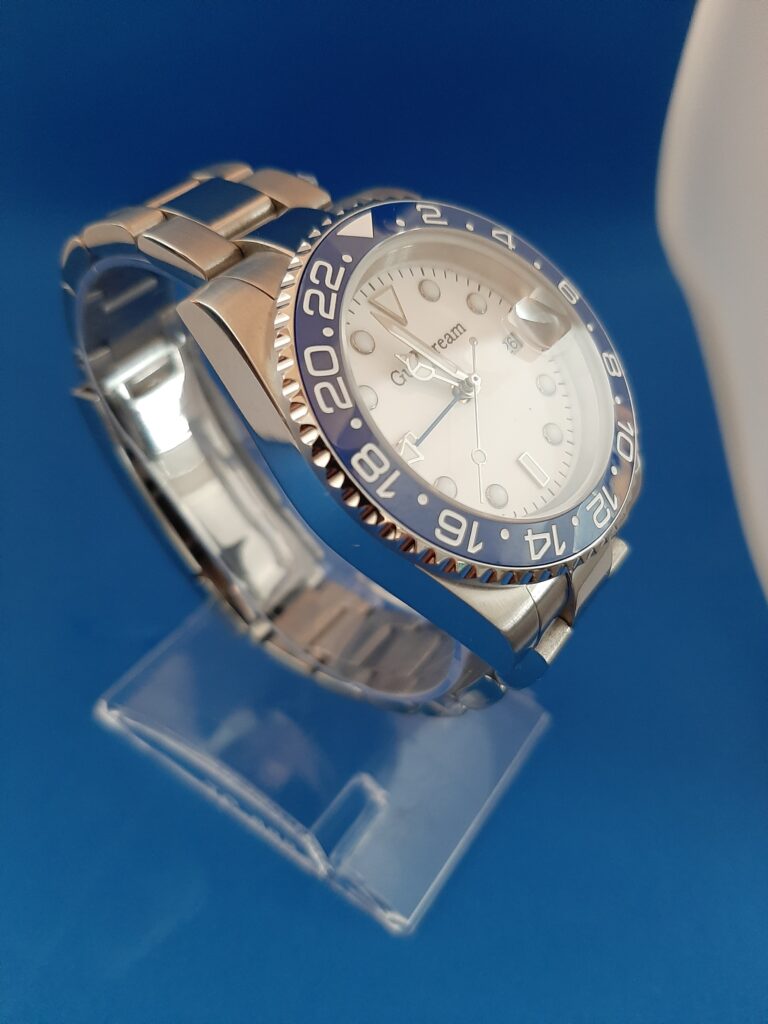

The band (bracelet) I use is the Oyster stainless steel band. To learn more about link styles, click on the Bands menu at the top of the page.

Weight

The watches are of high quality and have a nice heavy feel to them. They weigh an average of 5.3 oz. Nearly 1/3 of a pound.

How To Order

If you’d like to order a custom GMT watch from me, click on the menu link at the top of this page HowToOrder to see what options you can select from. Then contact me (email: ralphfreshour@gmail.com) so we can discuss your order and I can give you a rough idea where your order would be in my production queue.

You can message me on LinkedIn. You may also call me at 310.995.3864 and please note I am in the Los Angeles timezone. Once I have all of your parts ready, I will build your watch and send you pictures of it when I am finished. You can pay me at that time and I will ship your watch to you.

Single Order Processing

I work on orders on a first come first served basis. This means if I am working on four watches and receive an order from you, I will finish and ship those four watches before I start work on your watch.

Multiple Order Processing

Sometimes I receive orders from flight departments for a group of watches that a Chief Pilot or other Manager wants to purchase and give to their pilots as gifts.

Because I am a small watch building shop, I try to give the time and attention to all of my customers. If I get an order from a flight department for, let’s say 20 watches (yes, it happens all the time), I will divide that order up into working groups. In the case of 20 watches, I will work on 5 watches at a time in one group. Then I will work on some single watch orders. Then I will go back and work on another 5 watch group. In other words, I don’t want large flight department orders to adversely delay single order builds. But I want to be responsive to large flight department orders too. Sometimes I have to walk a tight rope.

The primary thing that causes the delay from the time you place your order and when I ship it, is the parts ordering process itself. Again, I’m not a big watch shop so I don’t have thousands of Dollars of watch inventory sitting around waiting to be used. I basically have to order the parts as the orders come in.

We have to also remember that I offer options. There is no way I can afford to stock every kind of custom watch option I offer so it really is better to just order your parts when you place your order.

Thank you.