I use a 40mm stainless steel case for all of my GMT watches. The cases I seal closed when I build them, but they are not designed to be a water sports watch. The recommendation is to not get them wet and certainly do not scuba dive with them. I do not pressure test them for diving.

The main issue with being around water (swimming, showering) and possibly getting them wet, has to do with the screw in crown. If by accident you forgot to screw in the crown, water will get into the case and ruin the movement. If the crown is screwed in snug (not tight), the case will be sealed. But I still don’t recommend showering or swimming with the watch due to the possibility of forgetting to screw in the crown.

These cases were designed to hold mechanical movements. Therefore I had to design my own movement holder that would fit inside the case. I designed and then 3D print these movement holders and they fit like a fine leather glove. My design went through 47 updates (really) before I declared it production ready.

Case Back

Important: Do not unscrew/remove the case back! There is an o-ring that has been lubricated and the case back has been installed with a certain amount of torque. Any changes to this may result in water getting into the case if you get the watch wet.

When the time comes to change the battery, you can send the watch to me or take your watch to a watch repair shop to have this done. They will know how to re-install the case back properly.

Engraving

I can engrave text on the back of the case. I charge a small fee to do that due to the additional work involved to prepare the text and set up the laser for engraving.

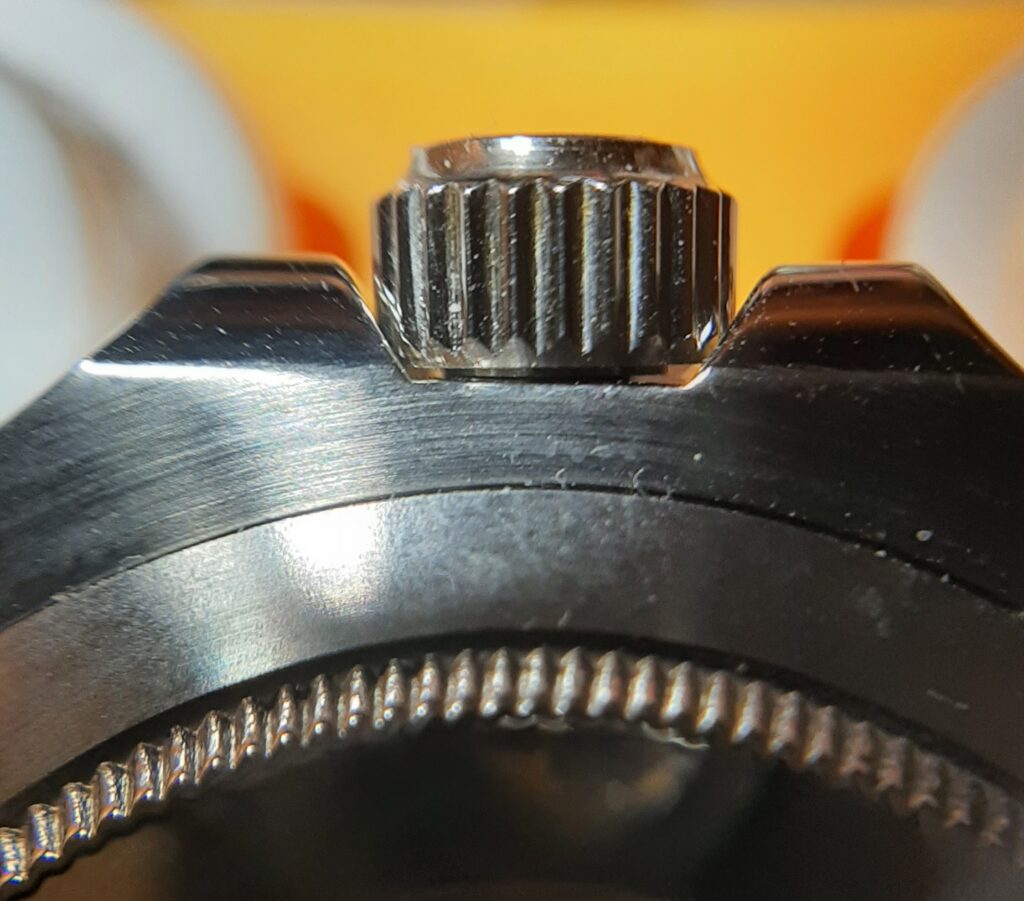

Screwing in the Crown

Use caution when screwing in the crown. Do not screw it in too tightly. Snug is good enough! The end of the case threads seal against a rubber gasket that is inside the crown, not from screwing the crown it in until it touches the case.

The photo below shows a crown screwed in snugly. Note that the crown does not need to touch the case in order to be sealed.

Cyclops

I normally add a cyclops to the crystal. The cyclops is the small window bump over the dial date digits to magnify the date display. If you prefer not to have a cyclops installed, let me know and I will skip this step during your watch build.

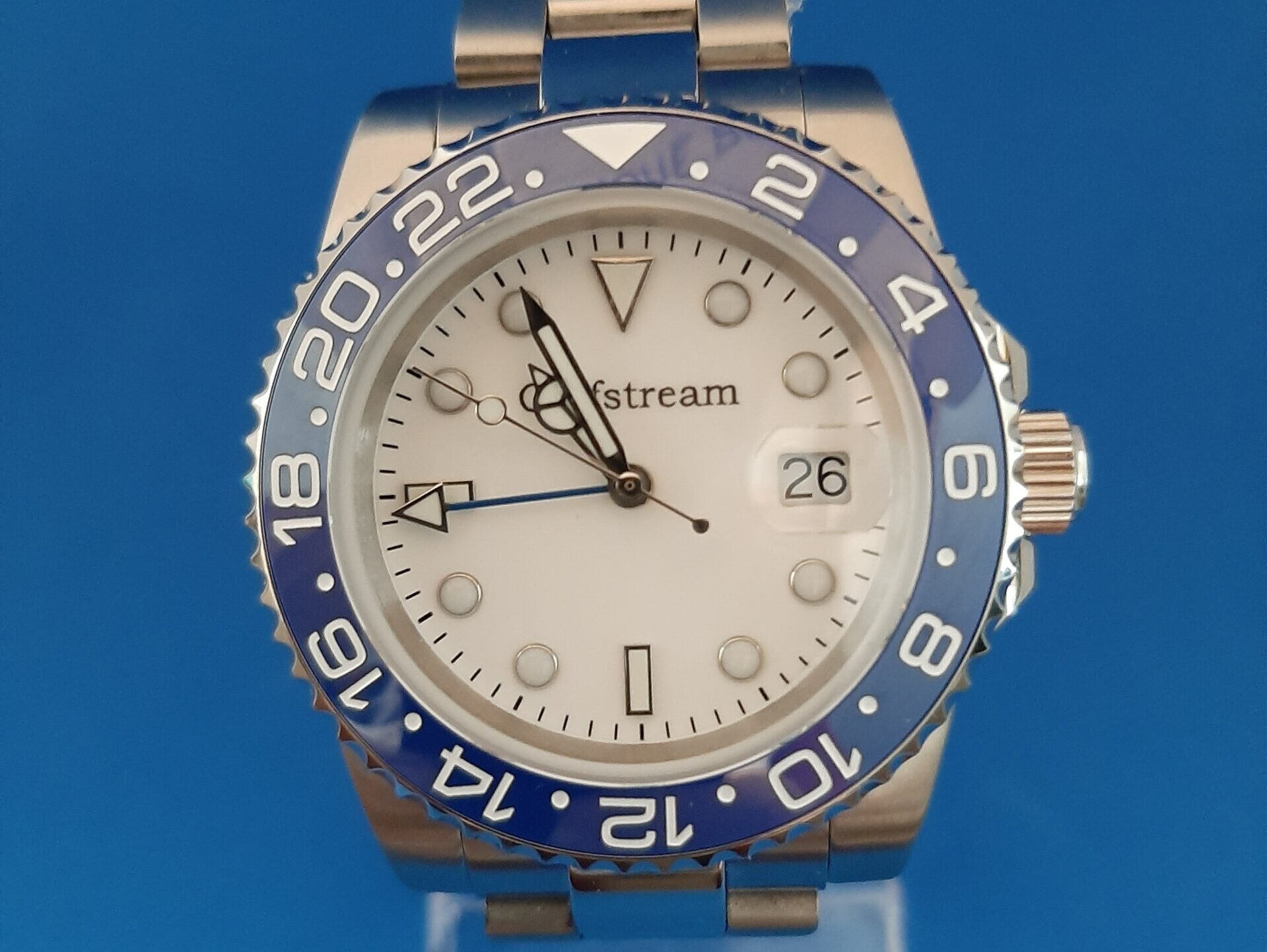

This photo (below) shows an example generic watch with the cyclops installed:

This photo (below) shows an example generic watch without the cyclops installed over the date window:

The Design: The Easy Road Not Taken

I wanted to explain why I did not take the ‘easy road’ to selling GMT pilot watches. Almost all of you reading this probably are not even aware there is an easier way to source and sell these kinds of watches. I took the long and more expensive road.

The above photo shows a completed blank dial (sterile dial) watches that I could have sourced and sold: a complete watch all ready to go. All the parts are there, including a movement. The movements however, on ALL of these watches are mechanical movements, not quartz (battery powered). There are no commercial blank dial GMT watch styles that you can buy that have a quartz movement.

All I would have to do if I were to buy these completed watches is remove the dial, remove the hands (very delicate task requiring special tools) and apply my custom logo text onto the dial, reassemble the watch and then resell. All very easy to do (for me) and no problems right? Well, not quite. There is one problem with this approach: the mechanical movement itself. The heart of a watch.

Unless you pay twice, or three times, what I charge for my GMT pilot watches, for a genuine ETA mechanical movement, you really won’t know what kind of movement will be in your watch. Chances are good it will be a clone of a clone of an ETA mechanical movement (made in China, Korea or Vietnam).

Even paying three times what I charge to get a genuine ETA movement, how would you ever know if that’s what you really got? You need a special tool to remove the back of a GMT watch case, so those watch factories know you’ll never remove the back and check.

I face the same problem. The chances are the suppliers of movements want to cut corners. So if I specify a genuine ETA mechanical movement, they might source me a Swiss ETA but with cloned parts inside it. Or they may source me a full clone or clone of a clone. I can’t afford to do business selling these kinds of movements because in the long run (or even in the short run) the movements will fail. And I’d have to double or triple the price of my watches and I really don’t want to do that.

Watch companies who make these completed sterile dial watches are putting in the cheapest mechanical movements possible. To get their costs down, these companies are now making cloned movements of cloned ETA movements. What does this all mean? It means that these watches would have an excellent chance of not working within a few months because of the cheap mechanical movements inside them. And to make matters worse, most watch repair shops will not work on cloned ETA movements.

This is why I chose not to go down this path. I chose to use a reliable and relatively affordable, Swiss made, quartz movement that will last years. And the added benefit is that I don’t have to wind the movement and set the time and the 24 hour hand, again, if I were to lay the watch on my dresser for a few days. And last but not least, it also means I can keep my prices down (at least compared to a watch that reportedly has a genuine ETA mechanical movement).

So my choice is to use a Swiss made quartz movement, design a 3D printed movement holder so the movement fits correctly inside the case, use a ‘classic’ GMT sterile dial design which requires the hands to have taller shaft tubes. This in turn requires the hands to be custom made. And then hand assemble all of the required parts to form the completed watch. That’s a lot of extra work but it’s the only way I can assure an affordable and reliable GMT pilot watch.

No More ETA Movements

I don’t want to go into the details on this next topic because it’s a huge topic, but what I want to say is this: ETA (a Swiss movement company) has been in a very long (10+ years) legal battle with COMCO which is a (Swiss) fair business trade agency. ETA has threatened to stop selling their ETA mechanical movements. While this has not happened (yet), they have reduced their ETA production of mechanical movements. The bottom line is that it would be risky for any watch business to solely rely on sourcing ETA mechanical movements. Another reason I chose not to go down the ETA path.

Update — it looks like production of the ETA mechanical movements has finally slowed as some have predicted. I was just informed by my GMT case factory that they will not be manufacturing a new batch of GMT cases because of the questionable supply of ETA movements. While I don’t use an ETA movement, I do use their cases so now I have to try and find a new source to buy my GMT cases.